Our website is set to allow the use of cookies. For more information click here. If you are happy with cookies for advertising and personalisation, please click “Accept and continue” or simply continue browsing.

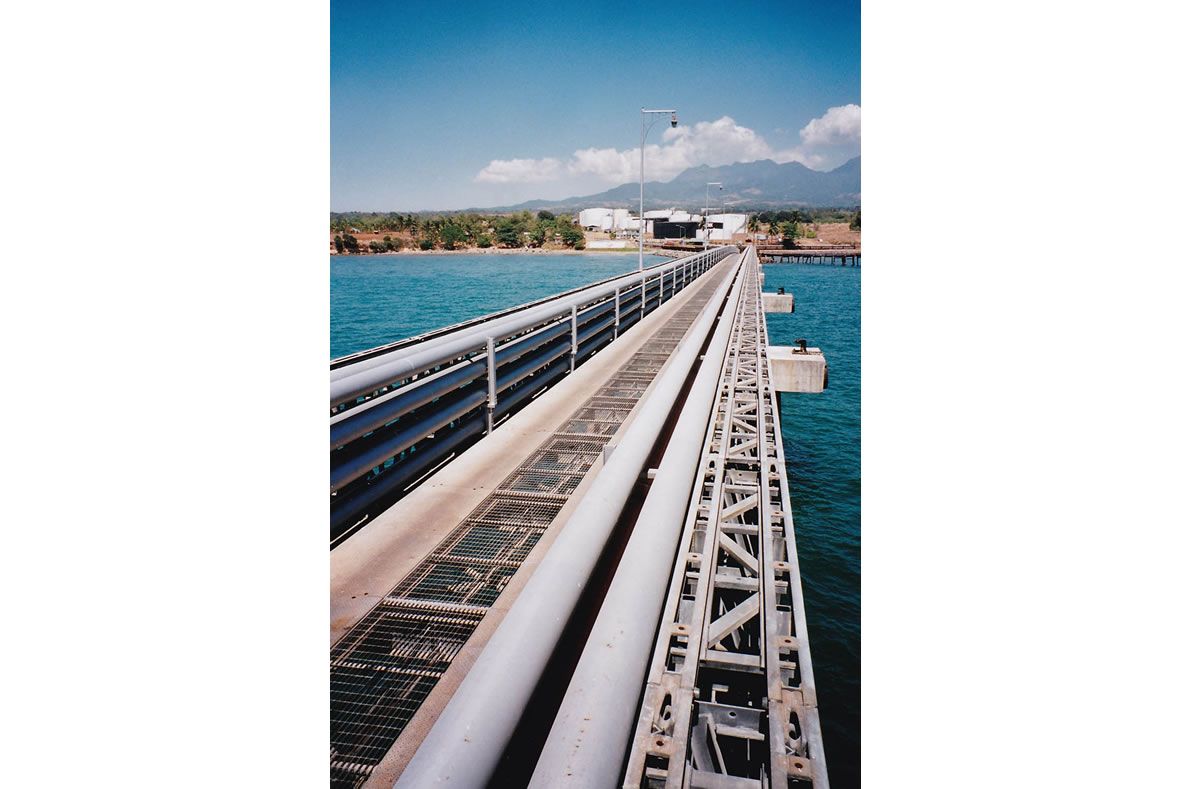

Oil Discharge Jetty, Philippines

- Oil and Gas, Energy and Pipelines

- Bridging, Engineering and Project Services

- Manila Bay, Philippines

The Challenge

The expansion of the Oilink facilities at Manila Bay in the Luzon region of the Philippines included the construction of a new unloading platform for oil discharge vessels. This platform would be reached by a jetty, which needed to have the capacity to accommodate the discharge from up to six vessels which could be simultaneously docked at the unloading platform. It also needed to be able to carry 42 tonne axle load vehicles.

The original scope of work for the project was to build a concrete structure, extending out into the bay, and supported on concrete piers. The piers would themselves be supported on pilings driven into the bed of the bay. However, after twelve months, only the piling work had been completed. Bad weather and lack of skilled labour were attributed to the delay, and the anticipated project deadline of 16 months was no longer on track.

Back to topThe Solution

Oilink understood that a delay represented an economical threat to the company’s operations at this facility and at its current rate, the project was not going to be delivered on time. An alternative plan was needed to find a quick and viable solution. Oilink sought advice from Mabey Bridge who came in to assess the site. Mabey Bridge recommended that a Compact 200™ bridge would be an ideal solution – it could be built using proprietary equipment that was widely available and it would more than adequately meet the technical specifications of the proposed platform.

As a point of interest, the piles, which had already been driven for the original concrete piers, were located at 17m intervals. If a modular panel bridge had been specified from the outset, the piers could have been installed at 40m intervals, resulting in a significant reduction in materials and labour.

During installation the Compact 200™ bridge was craned into place over the first three pilings. It was then cantilever-launched, with bays of bridging assembled on a work barge and lifted into position for fixing to the concrete piers.

The final section of the bridge jetty was assembled only 28 days after the initial launch.

Back to topThe Result

Oilink now has a fully functional jetty which was ready in a significantly shorter time-frame than had been feared after the initial piling work. The Compact 200™ bridge has accommodated several bespoke features, including an internal roadway with grid deck sections to allow for sea swell dispersal, a pipe rack at both sides to position discharge pipes from vessel to oil tanks, four unloading platforms and a manoeuvring platform at the end to allow vehicles to turn around.

Back to top